Professional Bearing Manufacturer and Supplier

Engineered Bearing Solutions

-

Ball bearing 6204 ZZ

-

Ball Bearings 6309 2RS for machinery use

-

Motor bearing 6202 ZZ

-

Produce fan bearing deep groove ball bearing 6301 2RS

-

Pillow Block Bearing UCP205 Durable Cast Iron High Load Bearing Performance

-

22317CAW33 Double Row Spherical Roller Bearing

-

Angular contact ball bearing 7303

-

NJ 304 Cylindrical Roller Bearing

Core Features & Technical Advantages of Our Bearings

Premium Material Selection

Precision Manufacturing Technology

Advanced CNC machining and grinding processes ensure ISO standard precision grades with tight dimensional tolerances

Advanced Sealing Solutions

Optimized Performance Engineering

Customization Capability

Advanced Bearing Manufacturing Process & Quality Control

Raw Material Selection & Inspection

Precision Forging & Heat Treatment

Flexible Customization & OEM Services

Bearing Assembly & Sealing Process

Rigorous Quality Testing & Inspection

Advanced Bearing Manufacturing Process & Quality Control

Our comprehensive manufacturing process integrates strict quality assurance at every stage:

Electric Motors & Industrial Equipment

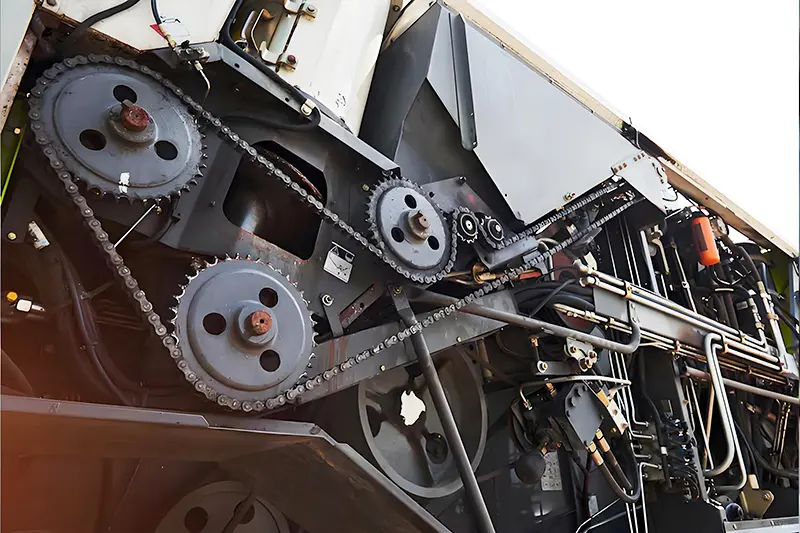

Agricultural Machinery & Material Handling

Heavy Industry & Mining Applications

Specialized Industrial Applications

Custom Bearing Solutions & Engineering Support

Bearing Material Selection

Special Sealing Configurations

Non-Standard Bearing Dimensions

Special Housing & Mounting Designs

Custom pillow block configurations including flange units and take-up frames

Bearing Selection Guide & Frequently Asked Questions

Q: How to choose between 2RS sealed bearings and 2Z shielded bearings?

Q: What are the advantages of spherical roller bearings for heavy machinery?

Q: Can your pillow block bearings withstand outdoor conditions?

Q: Do you offer food-grade bearing options?

Why Partner with Our Bearing Company?

01

ISO-Certified Bearing Manufacturer

with comprehensive quality assurance

02

Extensive Bearing Product Range

covering multiple types and specifications

03

Technical Engineering Support

for bearing selection and application optimization

04

Proven Track Record

serving global industrial clients across multiple sectors

05

Competitive Pricing

with direct manufacturer advantages

06

Reliable After-Sales Service

and technical consultation support

Get In Touch With Us For More Information

Contact Us

- +86-0574-63227016

- FLORY: +86 13857451900

- ALICE: +86 15168160140

- JASON: +86 13486462341

- RIGHT: +86 13454743115

- vetor@vetorgroups.com

- RM1407 SHINGER MANSION CIXI NINGBO CHINA

Send Us A Message

Rhoncus mi ac consectetur orci, feugiat enim morbi. Auctor rhoncus morbi