The 51105 thrust ball bearing is a single-direction thrust bearing belonging to the 51100 (thin-section) series, designed exclusively for axial load transmission. It conforms to international standards, with a nominal inner diameter of 25mm, outer diameter of 42mm, and thickness of 11mm, featuring a compact flat structure ideal for space-constrained axial load scenarios.

• Axial Load Specialization: It is engineered to carry pure axial loads (one direction only) and cannot withstand radial loads, making it highly efficient in applications where force acts along the shaft axis.

• Compact & Space-Saving: With a thin-walled design (minimal thickness relative to diameter), it occupies extremely limited axial space, fitting perfectly in equipment with strict size restrictions.

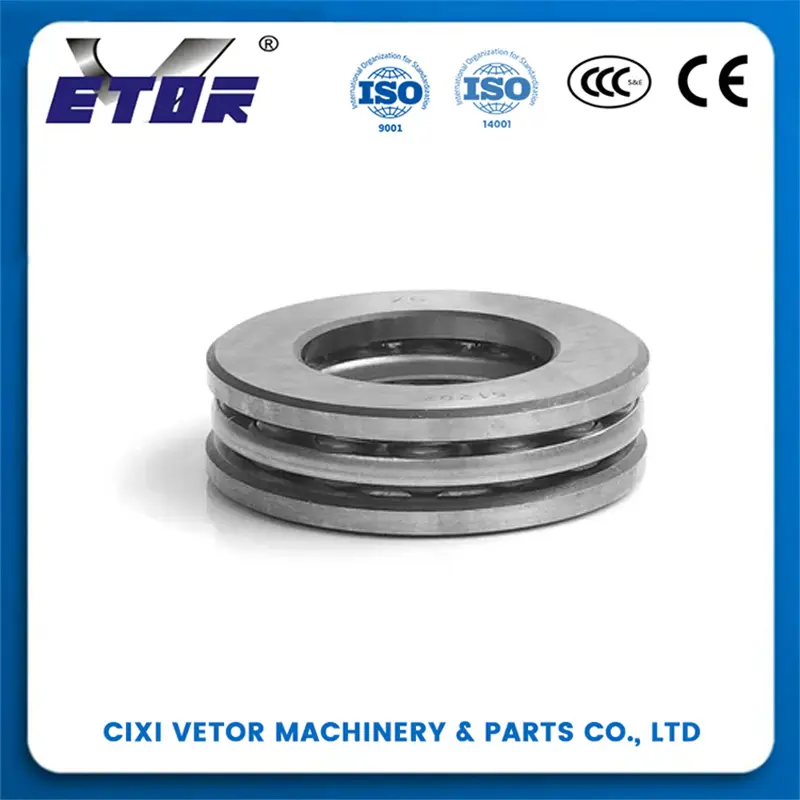

• High Rotational Precision: Composed of two precision-ground washers (shaft washer and housing washer) and a cage with steel balls, it ensures smooth rotation and low axial runout under rated loads.

• Easy Installation & Maintenance: Its separable structure (washers and cage assembly can be separated) allows straightforward mounting on shafts or housings.

1. Machine Tool Spindles: Used in the tailstocks and tool turrets of lathes, milling machines, and grinders. It provides stable axial positioning for the spindle, ensuring precision during cutting or machining operations.

2. Automotive Components: Applied in automotive transmission systems (such as gearbox end covers) and clutch release bearings. It bears the axial thrust generated during gear shifting and clutch engagement/disengagement.

3. Light Industrial Equipment: Essential in small pumps, compressors, and textile machine tension rollers. Its compact size and axial load capacity meet the lightweight and efficient design needs of these devices.

4. Instrumentation & Electrical Devices: Used in the rotating parts of precision instruments (like centrifuges), small electric motors, and household appliance components (e.g., air conditioner fan shafts). It delivers low-noise, high-precision axial support for small-scale rotating mechanisms.

Our robust production capability allows us to provide a wide array of solutions, helping you reduce downtime and enhance operational reliability.