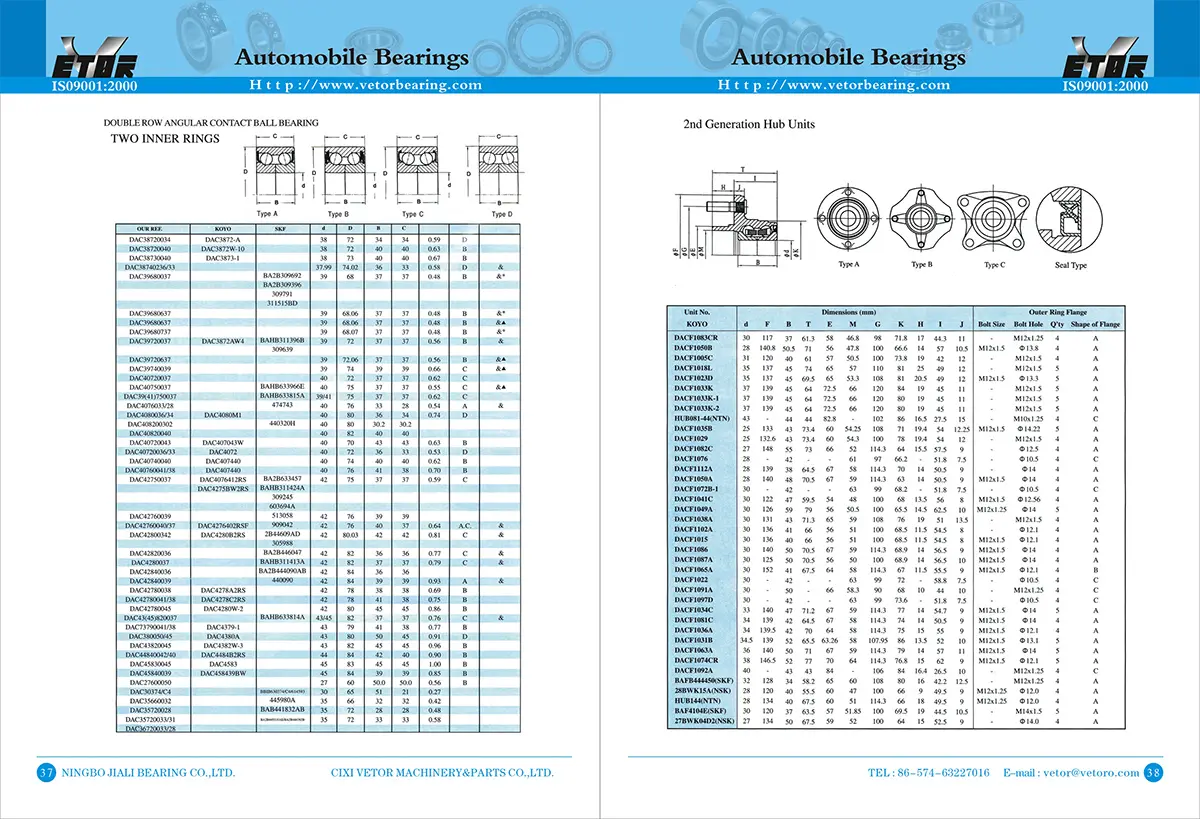

1. Integrated Compact Design: Integrates bearing, flange, and seal into one pre-assembled unit, simplifying installation, reducing wheel-end space occupation, and avoiding assembly errors.

2. Strong Combined Load Capacity: Optimized angular contact structure bears heavy radial loads (vehicle weight) and bidirectional axial loads (cornering/braking), withstanding sudden road impacts stably.

3. Excellent Sealing & Durability: Equipped with multi-layer rubber lip seals and metal dust covers, it effectively blocks water, dust, and road salts, preventing lubricant leakage and internal corrosion.

4. Low-Noise & High Precision: Precision-machined raceways and high-quality steel rolling elements minimize friction; advanced lubrication technology ensures low rotational noise and long service life (up to 150,000+ km).

1. Passenger Cars: Matched to compact and mid-size passenger cars (e.g., hatchbacks, sedans), serving as front/rear wheel hub bearings, ensuring smooth driving and ride comfort.

2. Light Commercial Vehicles: Applied in light vans, mini-trucks, and MPVs, adapting to frequent start-stop and moderate load changes in urban logistics or passenger transport.

3. New Energy Vehicles (NEVs): Suitable for small electric cars and plug-in hybrids, with low-friction design reducing energy consumption and matching electric drivetrain requirements.

4. Special Light Vehicles: Used in light modified vehicles like urban electric logistics vehicles and small recreational vehicles, meeting wheel-end reliability needs in specialized scenarios.

Our robust production capability allows us to provide a wide array of solutions, helping you reduce downtime and enhance operational reliability.